Fan Group

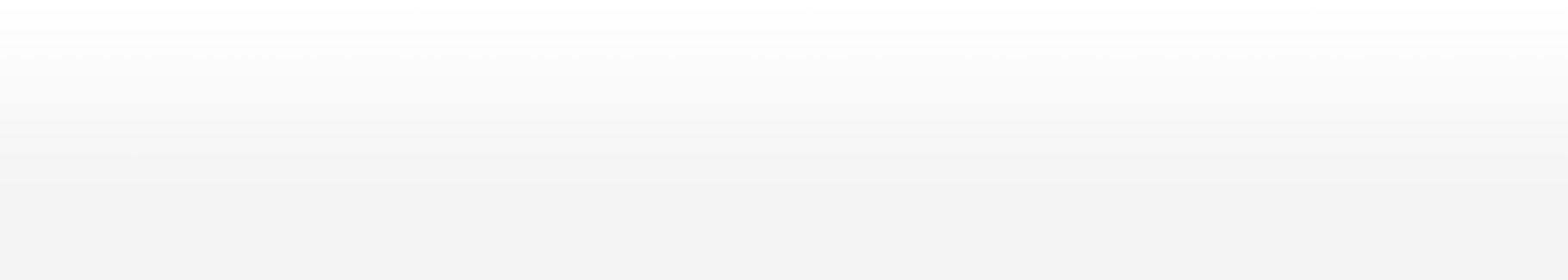

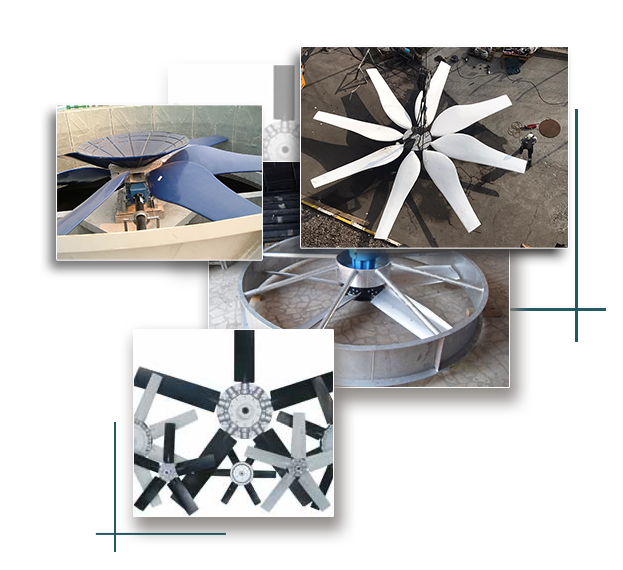

The fan group is located in the fan stack in the deck section of the tower. In order for evaporation to take place, it ensures that the outside air is sucked in, passed over the cooling fills and discharged into the atmosphere through the fan stack.

Direct coupled motor reducer group or horizontal input - vertical output reducer and related mechanical group elements are used in our towers.

*In direct coupled system, the electric motor is directly connected to the gearbox shaft and thus saves energy. Since there is no need for transmission organs such as shafts, belts and pulleys in the system, maintenance costs are low and the possibility of problems is reduced.

*Horizontal input - vertical output reducer and related mechanical group elements: fan, shaft, electric motor, fan shaft etc. It consists of material and functional elements suitable for operating conditions.

The vibration switch is located at the top level (roof section) of the tower.

The vibration switch is located at the top level (roof section) of the tower.

Yolyapı, which has been producing cooling towers since 1982, is ready to produce the most suitable water cooling tower solution for your company / facility with our expert team. Ask for a quote right away.